- Call: +86-13584426116

- Email: info@borun-machinery.com

- Get a Quote

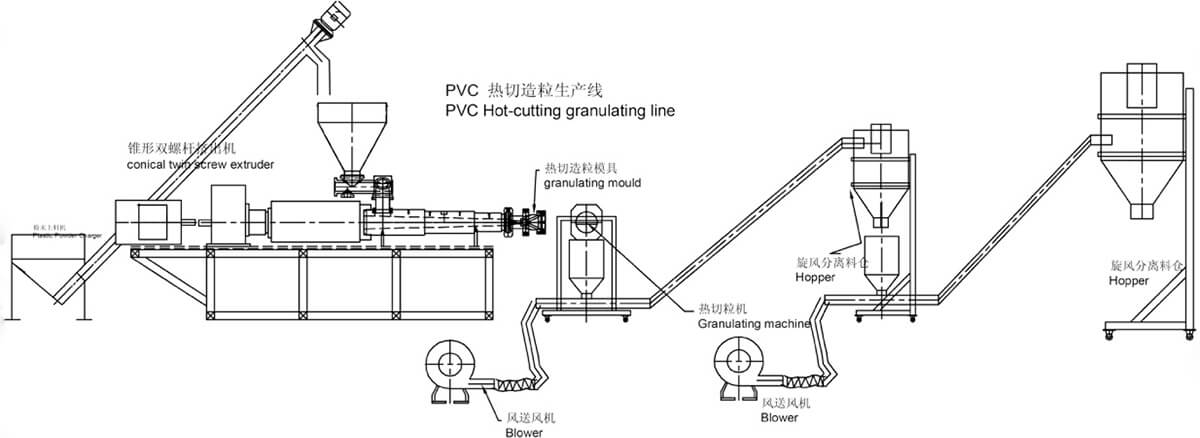

This PVC hot cutting pelletizing line is composed of a conical twin screw extruderand the corresponding granulating equipment, it is suitable for pelletizing of PVC, PE rawmaterials with wood power or other additives.

The pellets produced by this machine is evenly, solid, elegance.

The pelletizing downstream equipment includes die face cutter, air transferring unit, vibration separating, hydraulic net changer, etc. The machines are high automation and good production efficiency.

It can fine plasticizing, high productive efficiency, impact construction in the whole line and high automatization.

5.PVC powder can mix with other materials, like CaCO3, CPE, Static, wax and so on. The granules can be used to producing PVC profiles, shoes and so on.

| Model | SJSZ51/105 | SJSZ65/132 | SJSZ80/156 | SJSZ92/188 |

| Main Extruder Power (KW) | 18.5 | 37 | 55 | 90 |

| Production Pipe (KW) | 15 | 24 | 36 | 87 |

| Fan motor Power (KW) | 2.2 | 3 | 4 | 4 |

| Cutting Motor Power (KW) | 1.1 | 1.5 | 2.2 | 2.2 |

| Production Capacity (kg/h) | 120-180 | 150-250 | 250-450 | 500-700 |

| Cutter Diameter (mm) | 200 | 250 | 280 | 320 |

| Granule Size (mm) | 3*3 | 4*4 | 4*4 | 5*4 |

| More Info? | Click | Click | Click | Click |

PVC compounding loading machine

Extruding machine

Pelletizing machine

air blowing convey system

storage tank

Vibrating separator

Air blowing system

Storage tank

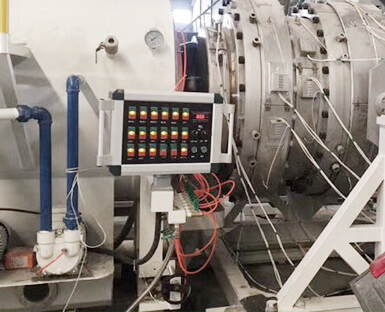

Conical Twin Screw Extruder with Auto Loader

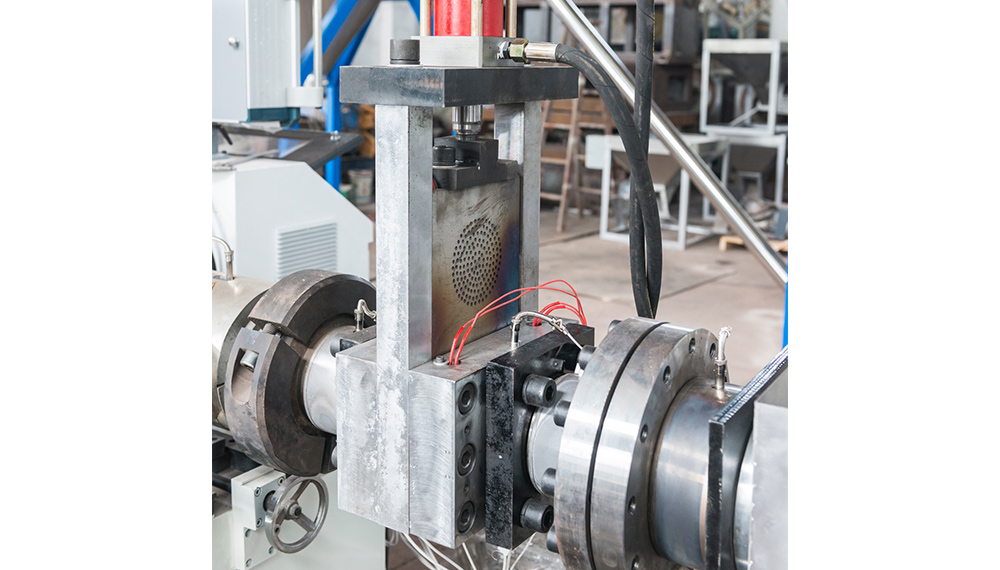

Hydraulic Net Changer

Hot Cutting Pelletizer

Cyclone blower and hopper dryer

Vibrating Separator

PVC Mixer Unit

PVC Pulverizer