- Call: +86-13584426116

- Email: info@borun-machinery.com

- Get a Quote

Plastic extruders can be divided into single-screw extruders, twin-screw extruders and multi-screw extruders according to the number of screws. At present, it is widely used in single-screw extruders and is suitable for extrusion processing of general materials. The twin-screw extruder has less heat generated by friction, the shearing of the material is relatively uniform, the conveying capacity of the screw is larger, the extrusion amount is relatively stable, the material stays long in the barrel, and the mixing is uniform.

The conical twin-screw extruder has the characteristics of forced extrusion, high quality, wide adaptability, long service life, small shear rate, difficult material decomposition, good mixing and plasticizing performance, direct molding of powder, temperature control, vacuum discharge Gas and other devices. It is suitable for the production of pipes, plates, profiles and other products.

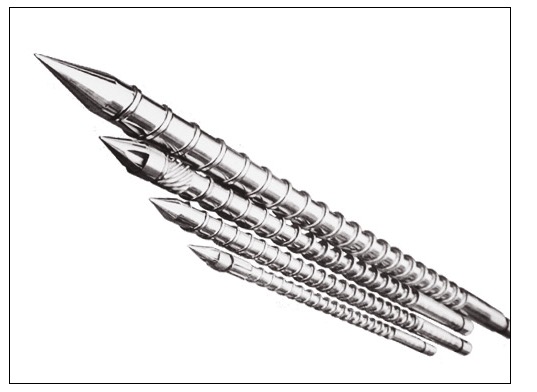

Single-screw extruders play an important role both as plasticizing granulation machines and forming processing machines. In recent years, single-screw extruders have developed greatly. At present, a large-scale single-screw extruder for granulation in Germany has a screw diameter of 700 mm and a yield of 36 t/h.

The main sign of the development of single-screw extruders is the development of its key component, the screw. In recent years, a large number of theoretical and experimental studies have been carried out on the screw. Up to now, there have been nearly 100 kinds of screws, and the common ones are separation type, shear-type, barrier type, split type and wave type.

From the point of view of single-screw development, although the single-screw extruder has been perfected in recent years, with the continuous development of polymer materials and plastic products, new-type screws and special single-screw extruders with more characteristics will emerge. In general, single-screw extruders are moving toward high speed and specialization.

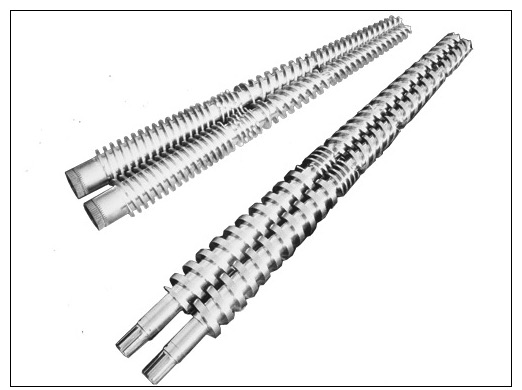

The twin-screw extruder has good feeding characteristics, is suitable for powder processing, and has better mixing, exhausting, reaction and self-cleaning functions than single-screw extruder. It is characterized by poor thermal stability and the processing of plastics and blends. It also shows its superiority. In recent years, foreign twin-screw extruders have been greatly developed. Various forms of twin-screw extruders have been serialized and commercialized, and there are many manufacturers. The classification is as follows:

(1) According to the relative position of the two axes, there are parallel and conical points;

(2) According to the two screw engagement procedures, there are meshing type and non-engaging type;

(3) According to the direction of rotation of the two screws, there are points in the same direction and in the opposite direction, and in the opposite direction, there are points inward and outward;

(4) According to the screw rotation speed, there are high speed and low-speed points;

(5) According to the structure of the screw and the barrel, there are integral and combined points.