- Call: +86-13584426116

- Email: info@borun-machinery.com

- Get a Quote

Application:

The HDPE/PE Pipe Extrusion Production line is mainly used to produce plastic PE pipes which are widely used as water pipe, gas pipe and electrical pipes.

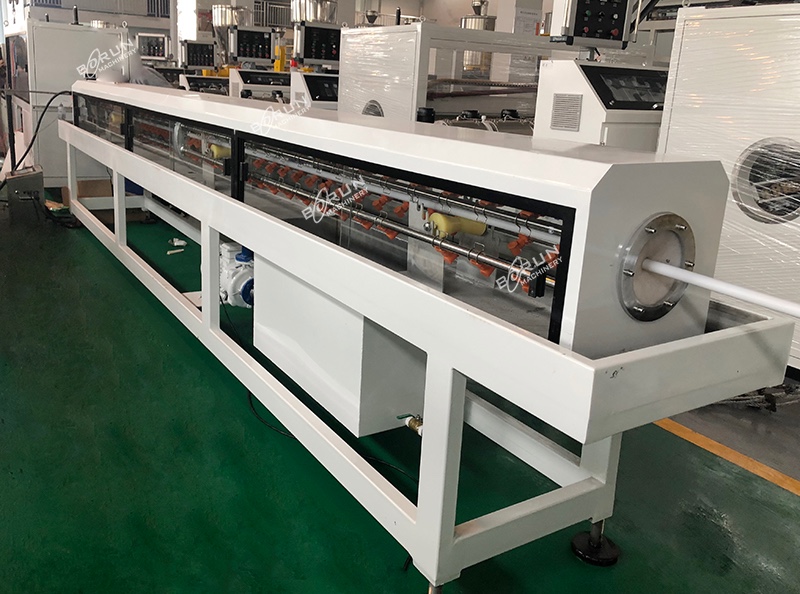

The extruder and PE pipe auxiliary equipment are reliablility applicability together, and provide strong certification for high quality plastic pipes for customers. The production line adopts high efficiency single screw extruder, equipped with high quality extrusion pipe mold, vacuum calibration tank, spraying cooling tank, haul off machine, non dust cutting machine and pipe stakers.

Features:

1. Extruder heads adopt adavanced basket and helx double heads;

2. Easy operation and equality extrusion;

3. Unique opening flume and water cooling for calibration molds;

4. High precision on pipe extrusion molds;

5. High Efficiency co-extruder for pipe color lines.

Plastic Single Screw Extruder

Vacuum Calibration Tank (Stainless Steel)

Spraying Cooling Tank(Stainless Steel)

PE Pipe Extrusion Mold

Haul Off Machine

Cutting Machine