- Call: +86-13584426116

- Email: info@borun-machinery.com

- Get a Quote

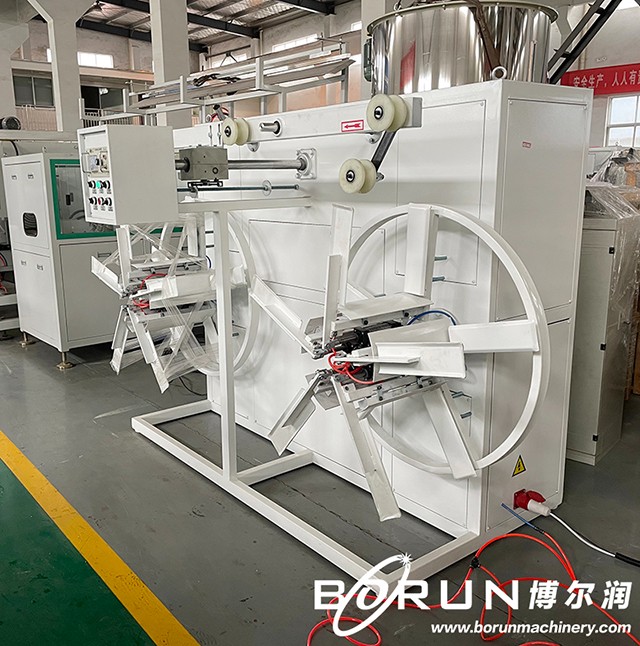

PE carbon spiral pipe production line is a kind of plastic pipe equipment used to produce PE carbon spiral pipe

PE Carbon Spiral Reinforced Pipe Extrusion Production Line

Description:

This extrusion line is mainly used for producing PE/HDPE carbon spiral reinforced pipe. PE carbon spiral pipe production line is a kind of plastic pipe equipment used to produce PE carbon spiral pipe. The plastic pipe production line synthesizes and modifies materials such as polyethylene and carbon, and is spirally formed by an extrusion process. PE carbon spiral pipe It has the advantages of PE plastic and carbon material, and has the characteristics of flame retardancy, insulation, strong ring stiffness, and good pressure resistance.

Application:

PE carbon spiral pipe has a broad market application field, such as: used in construction, chemical industry, miners, agricultural irrigation, water conservancy, electric power and other fields, especially in the current development of power infrastructure in my country, a large number of wires and cables are buried in the ground, carbon Plain spiral tube is an irreplaceable product.

Features:

Single screw extruders especially used for polyolefine material possess effective plasticizing effect and high extrusion speed.

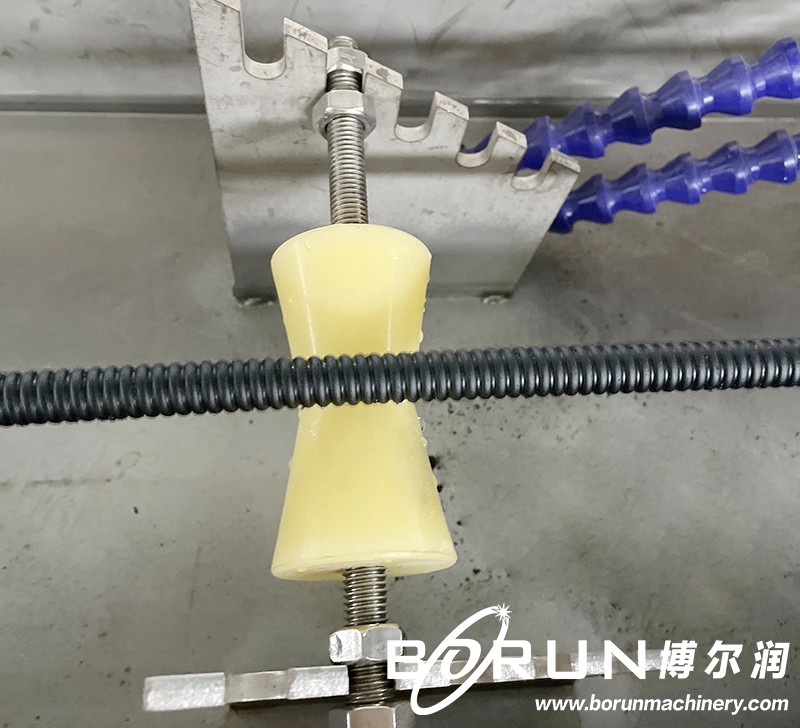

• The special detachment type mixing screw and the standard designed die with spiral structure & reasonable channel are applicable to produce with smooth inside and outside face.

• All kind of polyolefine material, multi-layers spiral strengthening pipe can be co-extruded for various uses, 80% of recycle material can be used in production;

• Optimum spiral copper sizing sleeve, its entrance carrying pre-cooling and powerful vacuum device to suit for high speed extruding pipe.

• Specific design for spray cooling trough.

• Cooling water trough is made of stainless steel

• High efficient cooling comes from peculiar spraying nozzle and high efficiency water pump.

• Three-dimensional regulation, longitudinal move by motor.

• Advanced co-extrusion technology and low cost to use recovery material.